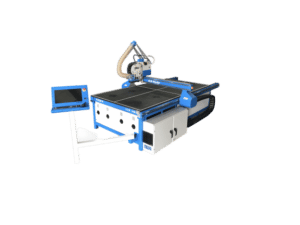

Cutting, sculpting, engraving, and carving materials with the use of CNC router tables are done in a range of industries. A computer-controlled router spindle in these tables precisely executes predetermined instructions to generate intricate forms and precise cuts. We’ll examine the primary uses and benefits of CNC router tables in this article.

In industries including carpentry, metallurgy, plastics manufacture, and sign-making, router tables are essential tools. They are designed to automate and streamline the precise and effective cutting, carving, and engraving of materials. These industries have undergone a revolution as a result of how many advantages CNC router tables have over earlier manual techniques.

Versatility of CNC Router Table

One of the main benefits of CNC router tables is their versatility. Various materials, including wood, plastic, foam, composites, and nonferrous metals, can be cut and shaped with these tables. A CNC router table is capable of handling a variety of tasks, including intricate designs, lovely patterns, and precise parts.

Additionally, CNC router tables are excellent for cutting and engraving tasks. They are able to develop intricate and exact designs with a great degree of accuracy, which enables them to produce custom goods, signage, and artwork.

Precision and Accuracy

Consistency is key in manufacturing, and router tables excel at providing it. Computer-controlled cutting ensures precise cuts, crisp edges, and smooth finishes. You can obtain precise tolerances and maintain consistency throughout the manufacturing process using a router table.

Additionally, router tables are highly repeatable, which makes them ideal for batch manufacturing. The machine can accurately reproduce a design once it has been designed, guaranteeing constant quality across multiple components.

Savings in Time and Effort

CNC router tables speed up and reduce the amount of time needed for manufacturing. By automating cutting processes, these robots reduce the need for manual work and the likelihood of human error. A router table can increase throughput and productivity.

A CNC router table may be set up more quickly than using manual techniques. Once the design has been programmed, the machine might start producing right away. There is no need for intricate measurements, labeling, or manual adjustments. This accelerated setup time allows for quicker project turnaround.

Cost-Effectiveness

Numerous factors make router tables economical. They first maximize the use of materials. Precision cutting capabilities of CNC router tables minimize waste by maximizing the use of raw materials. Significant cost savings are the consequence, especially for pricey materials or lengthy production cycles.

Rework and scrap are also decreased using CNC router tables. Precision cuts and machining significantly reduce the need to rework defective goods. This reduces costs by saving resources and time.

Individuality and Flexibility

Customization and flexibility for a range of applications are possible with router tables. The creation of unique and tailored items is made possible by the ability to program a variety of designs and patterns. Complex shapes, intricate inscriptions, and sophisticated woodwork can all be easily handled by a router table.

Additionally, CNC router tables are easy to change and enhance. As technology advances or your business’s needs change, you may upgrade your router table with new functions, software updates, or additional tools. Because of its versatility, your equipment is always current and prepared to meet shifting demands.

CNC router tables play a significant role in contemporary production. Because of their variety, accuracy, efficiency, cost-effectiveness, and customizability options, they are a crucial tool for businesses of all kinds. These tables give firms the ability to make high-quality goods while minimizing waste, saving time, and keeping competitive in a market that is continuously changing by exploiting the possibilities of CNC technology.