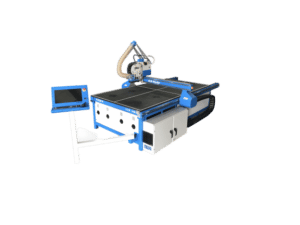

Maximizing efficiency is essential in today’s fast-paced industrial sector to remain competitive and satisfy customer needs. The CNC router table is one place where effectiveness is very important. On the CNC router table, workflow optimization can help you save time, cut expenses, and ultimately boost productivity. We’ll look at some important tactics in this blog post to assist you maximize productivity and streamline your workflow on the CNC router table.

Maximizing Efficiency by Preparation and Planning:

It is crucial to take the time necessary for careful planning and preparation before you even start working on the CNC router table. To do this, make a thorough production schedule, list the required equipment and supplies, and confirm that all files and designs are prepared for machining. You may reduce downtime and get rid of pointless delays by having a well-defined plan in place.

Maximizing Efficiency by Material Optimization:

Making the best use of your materials is a good approach to increasing productivity on the CNC router table. To reduce waste, parts are precisely nested inside the available area. You may increase material use and lower overall manufacturing costs by using software that can automatically build effective nesting patterns. Consider employing the proper cutting techniques as well to save material waste and extend the tool’s life.

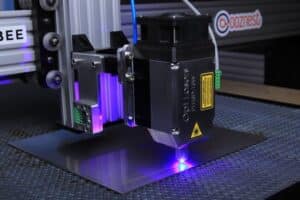

Maximizing Efficiency by Tooling Techniques:

Effective machining on the CNC router table depends on choosing the appropriate equipment for the task. Better cut quality and less downtime are produced by high-quality cutting instruments that are kept in good condition. Check your tools frequently for wear and tear, and replace them as necessary. Additionally, by applying the right tooling techniques, such as toolpath optimization and adaptive toolpaths, cutting speed and overall effectiveness can be greatly increased.

Maximizing Efficiency by Automation and integration:

Increasing productivity on the CNC router table depends heavily on automation. Use software functions that support automation, such as batch processing and tool change optimization. You can free up crucial time and boost overall productivity by automating monotonous chores. To sped up the workflow and remove human data entering, think about linking your CNC router table with other industrial processes or systems.

Maximizing Efficiency by Workflow optimization:

To increase output on the CNC router table, a productive workflow is essential. Determine any potential bottlenecks or locations where your present workflow might be improved, then make the necessary adjustments. This could entail rearranging the physical arrangement of your workstation, optimizing the file-management procedures, or enhancing departmental communication. You can find chances for efficiency increases by regularly analyzing and improving your workflow.

Maximizing Efficiency by Continuous Training and Skill Development:

It’s essential to invest in your operators’ training and skill advancement if you want to maximize workflow on the CNC router table. Make sure your staff members are informed about the machine’s capabilities, adept at using the software, and aware about machining best practices. Encourage operators to attend training courses on a regular basis and to stay current on CNC technology. Professional operators can solve problems quickly and effectively while also maximizing production efficiency.

In conclusion, a comprehensive strategy is needed to maximize effectiveness and optimize workflow on your CNC router table. Everything plays a significant part, from careful planning and preparation through material optimization, tooling methods, automation, workflow optimization, and ongoing training. You can speed up CNC machining operations, cut expenses, and increase production by putting these techniques into practice. You will benefit from an optimal workflow on your CNC router table if you remain dedicated to assessing and refining your procedures on a regular basis.